Introduction

The objective of this web page is to convey the key identifying features of muzzleloader locks that have been converted from flint to percussion ignition. Since this website features old-time gunsmiths from the Pennsylvania counties of Bedford and Somerset, I have used photographs of percussion conversions of antique Bedford County locks.

L. Dietle

The typical steps in converting a typical flintlock to a percussion lock are:

In addition to modifying the lock, the process of converting a firearm from flint to percussion requires drilling and tapping the barrel for, and adding the drum and associated nipple. The presence of a cylindrical drum is not proof of a percussion conversion, because such drums were also used on many firearms that were originally built as percussion arms.

The hole for the frizzen screw

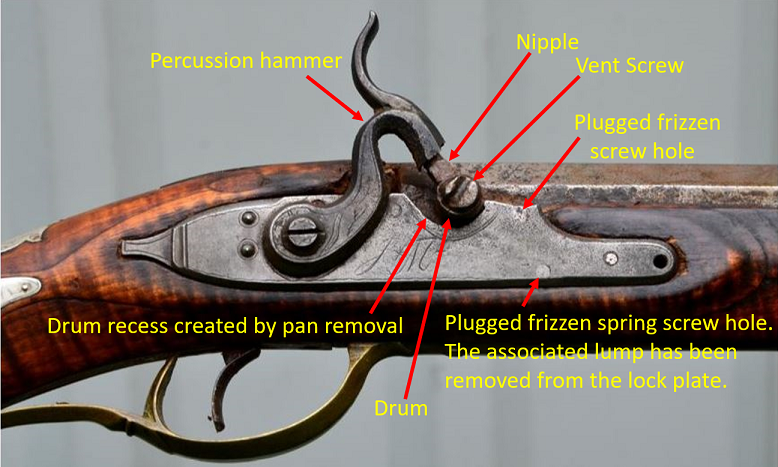

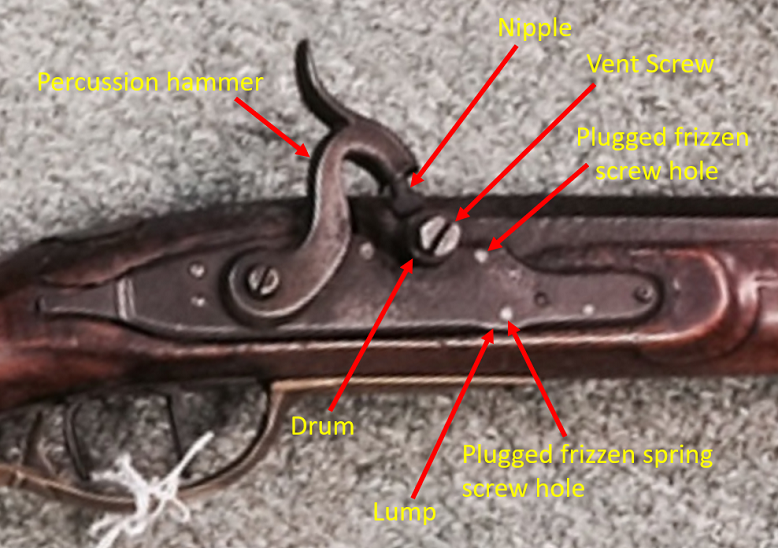

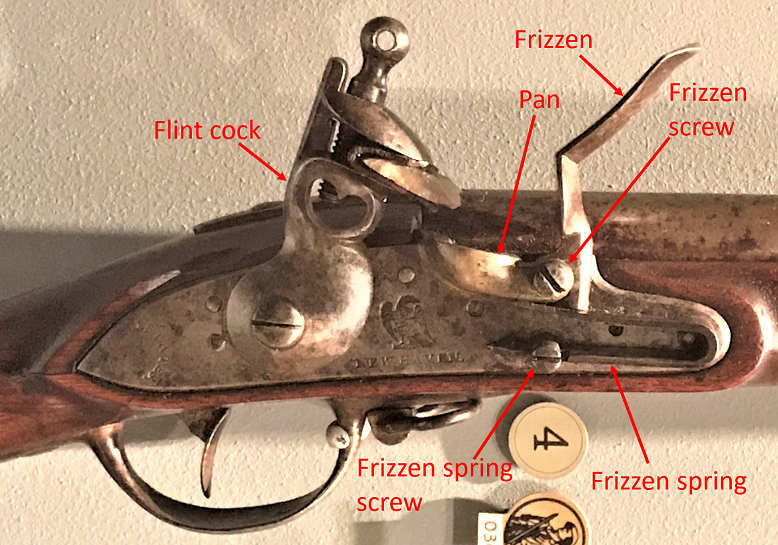

One important clue that a lock has been converted from flint to percussion is the frizzen screw hole in the lock plate. The hole is located forward of the drum recess in the lock plate. The frizzen screw hole typically plugged for asthetic reasons, as shown by the images of Bedford County-Pennsylvania-style percussion conversion locks that are included below.

Screw hole for the frizzen spring

Another important clue that a lock has been converted from flint to percussion is the screw hole that retained the frizzen spring to the lock plate. This screw hole, which is located near the bottom edge of the lock plate and forward of the drum recess, is typically plugged for asthetic reasons, as shown by the images below. On the very narrow Bedford County locks, the frizzen spring screw hole is often so close to the lower edge of the lock plate that a a "lump" is incorporated to provide a flat space surrounding the hole. In the first photo below, the lump was filed away during the percussion conversion to match the beveled profile along the rest of the lower edge of the lockplate.

Any visible remnants of the pan

In a percussion conversion, the drum recess is created by removing all or part of the flintlock pan. When all of the pan is removed, the resulting recess is typically shaped like the pan had been shaped, rather than fitting closely with the drum. When only part of the pan is removed, the remaining portion of the pan is an unmistakeable identifying feature of a flintlock conversion. On many (but certainly not all) rifles that were originally built with percussion ignition, the drum recess is a relatively close fit with the drum.

The first image below shows a percussion conversion Bedford County-style rat tail lock from a Joseph Mills smooth rifle.

The next image shows a percussion conversion Bedford County-style rat tail lock from a Jacob Stoudenour rifle.

The next image shows a percussion conversion Bedford County-style rat tail lock from a Joseph Mills rifle. A vestige of the flintlock pan is still visible. Click here to see another example of a percussion conversion rifle where a portion of the pan remains.

The next image is a flintlock from an Eli Whitney 1798 contract musket. I am including it to identify the lock parts that are removed when converting a flintlock to percussion: the flint cock, pan, frizzen, frizzen screw, frizzen spring, and frizzen spring screw. This photo shows that on wide locks no lump is required to accomodate the frizzen spring screw, because the screw is well away from the lower edge of the lock plate.

The next image shows an original percussion lock on a rifle that was made by J. H. Johnston's Great Western Gun Works of Pittsburgh, Pennsylvania. The drum recess on the lock plate fits relatively closely with the percussion drum.

Return to the Bedford & Somerset County Gunsmithing Index